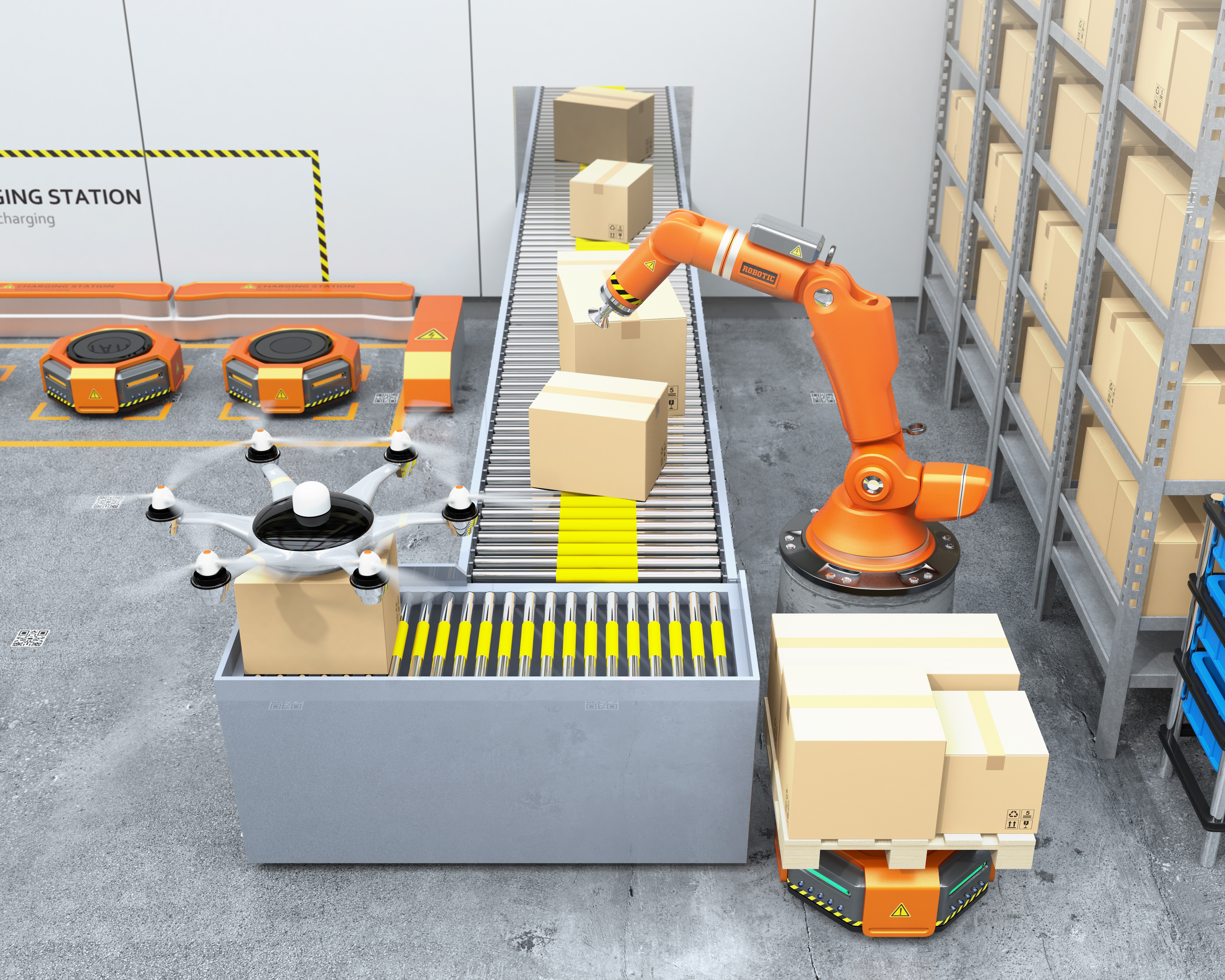

Warehouse logistics and processes can be complex. Honeywell continues to partner with logistics leaders for new ways to incorporate our products and experience into solving multi-faceted applications. We build on the strength of our past while keeping focus on the future with innovative solutions for up-and-coming applications.

Growth expected for the global warehouse robotics sector by 2025

$6.8 billion

50,000 robotic warehouses

4 million robots

The global warehouse robotics market was valued at USD 3.5 billion in 2019 and it is expected to reach 6.8 billion by 2025.1 Connected systems (both within the warehouse and the global network) are helping industries perform a multitude of tasks (batching, picking, ordering, packaging, and more) as ways to improve operational efficiency.

Think the Way Forward in Warehouse Automation

Sensors and Switches for Picking, Sorting & Placing

Picking is the most time-consuming warehouse activity, and accounts for countless work hours and more worker effort than any other aspect of warehouse operations. To address this growing inefficiency, many distribution centers and warehouses are deploying picker robots into their workforce. The robot efficiently gathers product(s) and brings them to a centralized area, where human workers can fulfill orders more efficiently.

According to the Bank of America, it is estimated that by 2025, 45% of all manufacturing tasks will be executed by robotic technology.1

Source: https://www.reportlinker.com/p05982346/Warehouse-Robotics-Market-Growth-Trends-Forecasts.html

Sensors and Switches for Product Movement

Warehouses typically rely on conveyors and other fixed machinery for product movement. However, warehouse operations managers are using Automatic Guided Vehicles (AGVs) to pick materials and handle repetitive, sometimes dangerous tasks. According to a May 2021 AGV Global Market Report from BCC Research, the use of AGVs has resulted in higher productivity, greater revenue generation and better resource allocation. The report also states that use of AGVs has created safer environments at workplaces, reduced accidents and efficient operations, thus, giving a boost to the growth and opportunities of the AGV market.

Sensors and Switches for Loading & Unloading

Few warehouse jobs are more arduous, repetitive and injury-prone than loading and unloading freight on the receiving dock. Not only are these jobs notoriously difficult to fill — especially in today’s shrinking labor market — but they also have some of the highest turnover rates. (The average dock worker stays at their job for less than one year, according to Zippia.com.) Automating all or part of the loading/unloading process can relieve workers from difficult tasks that are frequently uncomfortable to perform. This allows labor to be shifted to work that is more interesting and less physically demanding.

Force Sensors in Robotic Applications

As an integral component in robotic applications, force sensors have numerous strengths that can add value to these applications. Industrial and surgical robots are part of a quickly growing global market as they can enable work with humans without the risk of injury and can help conduct visual tasks like inspection and path following.

Contact us