-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partner

- |

- Blog

- |

- Contatta Honeywell

- |

-

Software

Software

-

Automazione

Automazione -

Produttività

Produttività-

Comunicazione e messaggistica

-

Business Intelligence

-

Gestione delle attività e della forza lavoro

-

Prelievo ed evasione ordini

-

Consegna

-

Logistica di ritorno

-

Gestione dei dispositivi

-

SwiftDecoder

-

Etichettatura con codici a barre

-

Strumenti di sviluppo

-

Browser ed emulatori

-

Sviluppo del software di scansione TotalFreedom

-

-

Sicurezza

Sicurezza

-

-

Servizi

Servizi

-

Automazione

Automazione -

Produttività

Produttività -

Sicurezza

Sicurezza

-

-

Settori industriali

Settori industriali

-

Assistenza sanitaria e scienze biologiche

Assistenza sanitaria e scienze biologiche -

Trasporto e logistica

Trasporto e logistica -

Produzione

Produzione -

Centri di distribuzione

-

Vendita al dettaglio

Vendita al dettaglio -

E-commerce

-

Infrastruttura

Infrastruttura -

Enti pubblici

Enti pubblici -

Industria aerospaziale e difesa

-

-

Assistenza

Assistenza

-

Automazione

Automazione -

Produttività

Produttività -

Sicurezza

Sicurezza -

Soluzioni di rilevamento

Soluzioni di rilevamento-

Modulo di contatto vendite

-

Technical Support

-

Sedi globali

-

Certificates

-

Blog (US)

-

Return Material Authorization (Test & Measurement)

-

Return Material Authorization (Citytech)

-

EnviteC - Return Material Authorization (RMA)

-

Distributor Inventory

-

eCOM Portal

-

City Technology Materials Safety

-

EnviteC Cross Reference List

-

-

-

Dove acquistare

Dove acquistare

Stai sfogliando il catalogo prodotti per

- Prodotti

- Automazione

- Solutions by Technology

- Conveyor Systems

- Curve Conveyor

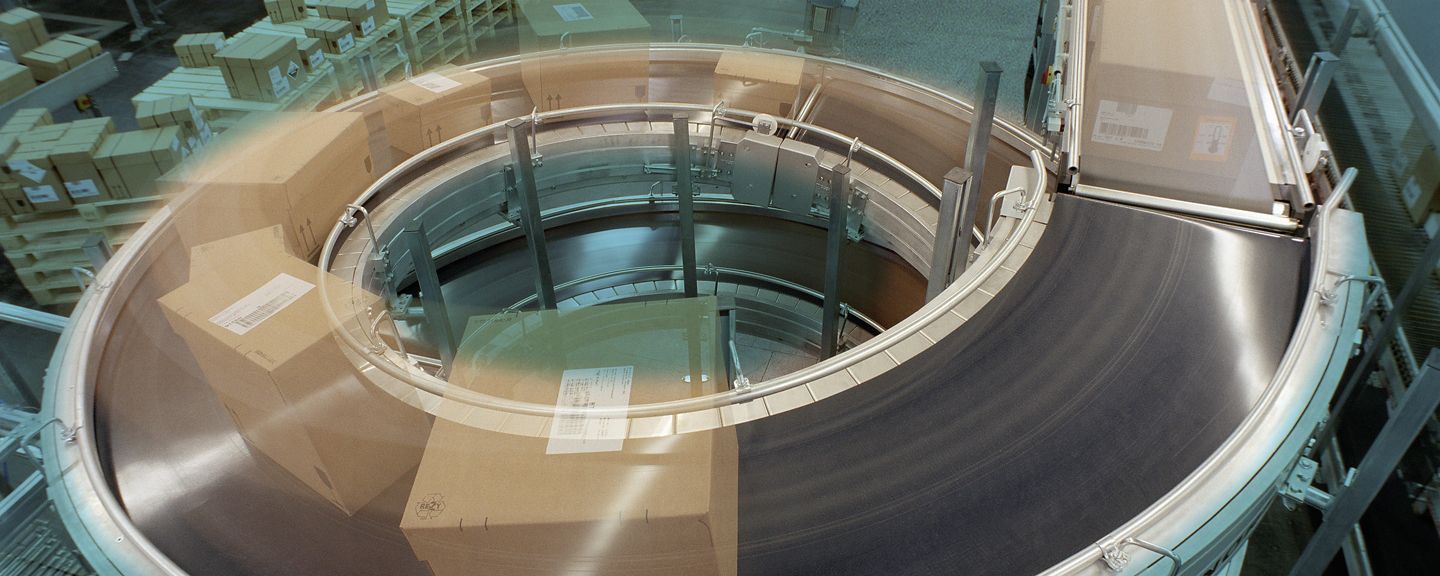

Curve Conveyors

Route Cases, Totes and Parcels in Any Direction With Curve and Spiral Conveyor Systems

With an install base of over 140,000 units, the reliability and robust nature of Transnorm’s flagship belt curve range is known and recognized worldwide as the industry standard and clear market leader. Boosting efficiencies as a key functional module at Parcel Hubs, Distribution Centers, smaller CEP sites and eCommerce Fulfilment locations across 5 continents. The reach also extends to over 300 Airports globally, including each of the top 30.

Intralogistics Curve – TS 1600-090

Transnorm Intralogistics Curve

Due to the patented belt guidance technology and conical pullies, the Transnorm Intralogistics Curves for single loads of up to 35kg/m stand out for high reliability and quiet operation. Transnorm Intralogistics Curves prove their performance and reliability day after day in numerous intralogistics applications and across the most diverse industries. Whether it involves the transport of bins, cardboard boxes or parcels, our maintenance-friendly belt curves ensure an accurate and smooth change of direction.

Transnorm Intralogistics Curves provide the following benefits:

- Best-in-class in performance, reliability, energy consumption and maintenance-friendliness

- Robust construction with low self-weight

- Optimized in terms of weight, space and installation

- Ease of integration in new and existing handling systems

- Patented belt guiding system and conical drums for maximum reliability and smoothness in running

- Low-tension conveyor belt drive across the entire width of the belt enables extremely long times of deployment

Standard Belt Curve – TS 1600-105 / TS 1500 (US Market)

Transnorm Standard Belt Curve Conveyor

The Standard Belt Curve Conveyors represent the core element of the innovative Transnorm curve conveyor family and can be used for a variety of applications for the transportation of packed and unpacked goods, with a maximum loading capacity of 150kg. Offering high performance and continuous operation, they are key element and commonly found throughout Baggage Handling Systems, Parcel sites and eCommerce Fulfilment centers.

Transnorm belt curves are renowned for their reliability and feature an integrated design concept. Minimizing the effective space requirement of an overall system and simplifying all manual operations including belt replacement.

The Transnorm Standard Belt Curve conveyor offers the following benefits:

- Best-in-class in performance, reliability, energy consumption and maintenance-friendliness

- Robust construction with low self-weight

- Optimized in terms of weight, space and installation

- Ease of integration in new and existing parcel handling systems

- Patented belt guiding system and conical drums for maximum reliability and smoothness in running

- Easy and fast belt change

- Low-tension conveyor belt drive across the entire width of the belt enables extremely long deployment times

Heavy Duty Belt Curve – TS 1600-140 / TS 1500-SPC (US Market)

Transnorm Heavy Duty Belt Curve Conveyor – Robust and Reliable

With standard nominal widths of up to 1,500mm and total load capacity of up to 250kg, the Transnorm Heavy Duty Belt Curves are an important solution for heavily loaded conveying routes or transport lines with irregular loads. Equally capable at low and high speeds, the Heavy Duty Belt Curves offers a maximum flow rate of up to 3m/s – the highest standards of performance and reliability.

Maintaining Transnorm’s cutting edge technology and fulfilling an eco-footprint to provide the lowest energy and maintenance requirements whilst also delivering the lowest noise levels for a module in this class.

The Transnorm Heavy Duty Belt Curve conveyor offers the following benefits:

- Best-in-class in performance, reliability, energy consumption and maintenance-friendliness

- Robust construction with low self-weight

- Optimized in terms of weight, space and installation

- Ease of integration in new and existing parcel handling systems

- Patented belt guiding system and conical drums for maximum reliability and smoothness in running

- Easy and fast belt change

- Low-tension conveyor belt drive across the entire width of the belt enables extremely long deployment times

Helix Belt Curves

Transnorm Helix Belt Conveyors - two functions, one conveyor, full speed...

Helix curves are used in conveyor systems when along with transport around a curve, there is also a level change to overcome. Thanks to the holistic construction concept, Transnorm Helix Belt Conveyors combine performance and reliability. In addition, the effective footprint and space requirement to fulfill this function is greatly reduced within the system layout. Also, belt replacement remains highly simplified.

Transnorm Helix Belt Conveyors provide the following benefits:

- Extremely high throughput

- Less controlling effort and no advance cyclic operation

- Patented belt guiding system and conical drums for maximum reliability and smoothness in running

- Low-tension conveyor belt drive across the entire width of the belt enables extremely long times of deployment

- Optimized in terms of weight, space and installation

- Very low noise levels compared to conveyors with chain drives

Global Airport Curve – TS 1600 GAC

Transnorm Global Airport Curve – Proven worldwide

The Global Airport Curve is the result of our constant drive to support the needs of baggage handling system operators and system integrators. The holistic construction concept combines the proven reliability of the Transnorm belt curves with best-in-class energy consumption, smooth operation and maintenance-friendliness. The results are considerably reduced life cycle costs and a high level of economy.

The Transnorm Global Airport Curve offers the following benefits:

- Best-in-class in performance, reliability, energy consumption and maintenance-friendliness

- Robust construction with low self-weight

- Optimized in terms of weight, space and installation

- Ease of integration in new and existing baggage handling systems

- Patented belt guiding system and conical drums for maximum reliability and smoothness in running

- Low tension conveyor belt drive across the entire width of the belt enables extremely long deployment times

- Belt slides on highly solid laminated wooden sheets

Roller Curve – TS 2730

Transnorm Roller Curve Conveyors – Flexible and efficient solution for curve transport

Transnorm Roller Curves offer a high efficiency, virtually maintenance-free solution for transporting light or boxed loads. Utilizing 24V roller technology, economical, motorized rollers require less electrical output compared to conventional drives.

Transnorm Roller Curve Conveyors with a motor roller drive provide the following benefits:

- Standardized, economical solution

- Compact / flat design and construction

- Driven via motorized rollers (24V technology)

- Only low installed electric power is necessary

- Low wear and tear and maintenance-friendly

- Extremely low-noise operation

- Subsequent adjustments can be made easily and quickly

Safeglide ® Spiral Chute

Safeglide® Spiral Chutes - Save energy while conveying with the force of gravity

The Transnorm Safeglide® Spiral Chute is a fast, safe and cost-effective solution for transporting packaged goods gently from one level to another.

The spiral chutes are designed from multiple fiberglass-reinforced epoxy resin coated layers. The sliding surface consists of a special finish in which the finest stainless steel balls are embedded, providing excellent sliding properties and reducing wear and tear. The Transnorm Safeglide® Spiral Chute can be combined with different guides delivering a dynamic buffer with safe, automatic gliding.

The Safeglide® Spiral Chute offers the following benefits:

- Safe and fast downward movement

- Noise-damping and flame resistant composite material

- Excellent gliding capability that remains unaffected even by unfavorable ambient conditions such as high atmospheric humidity

- Low procurement costs and low maintenance cost/effort

- No moving parts and no spare and wear parts

- Low-cost repair

Curve Conveyor

Mettiamoci in contatto!

Iscrivetevi per ricevere comunicazioni esclusive da parte di Honeywell su aggiornamenti di prodotti, informazioni tecniche, nuove offerte, eventi e notizie, sondaggi, offerte speciali e argomenti correlati tramite telefono, e-mail e altre forme di comunicazione elettronica.

Copyright © 2024 Honeywell International Inc

Dimensioni massime file

Numero massimo di file superato

A causa dell'inattività verrai disconnesso 000 secondi.