-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

-

Currency:Localize your Content

You can set your preferred currency for this account.

Choose a Currency

Currency- CHOOSE YOUR CURRENCY

Update Currency

Changing Currency will cause your current cart to be deleted. Click OK to proceed.

To Keep your current cart, click CLOSE and then save your cart before changing currency.

-

Select Account

Switching accounts will update the product catalog available to you. When switching accounts, your current cart will not move to the new account you select. Your current cart will be available if you log back into this account again.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Support

- View All Productivity Solutions

- Warranties

- Patents

- Global Locations

- Technical Support

- Discontinued Products

- Quality Program and Environmental Compliance

- Return Material Authorization (RMA)

- Legal Documents

- Product Certification

- Software Downloads

- Cyber Security Notifications

- Case Studies and Success Stories

- View All Sensing Solutions

- Sales Contact Form

- Technical Support

- Certificates

- eCOM Portal

- Distributor Inventory

- Return Material Authorization (Test & Measurement)

- Return Material Authorization (Citytech)

- Return Material Authorization (EnviteC)

- Legal Documents

- Intelligent Life Care

- Return Material Authorization (ILC)

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- News & Events

- Featured stories

- Detection, Measurement & Control Solutions

- Electrical safety gear - how is it critical to lineman?

Electrical safety gear - how is it critical to lineman?

Electrical safety gear - how is it critical to lineman?

Russ Owen

October 25, 2022

The history of electrical safety gear and how it’s critical to lineman safety today

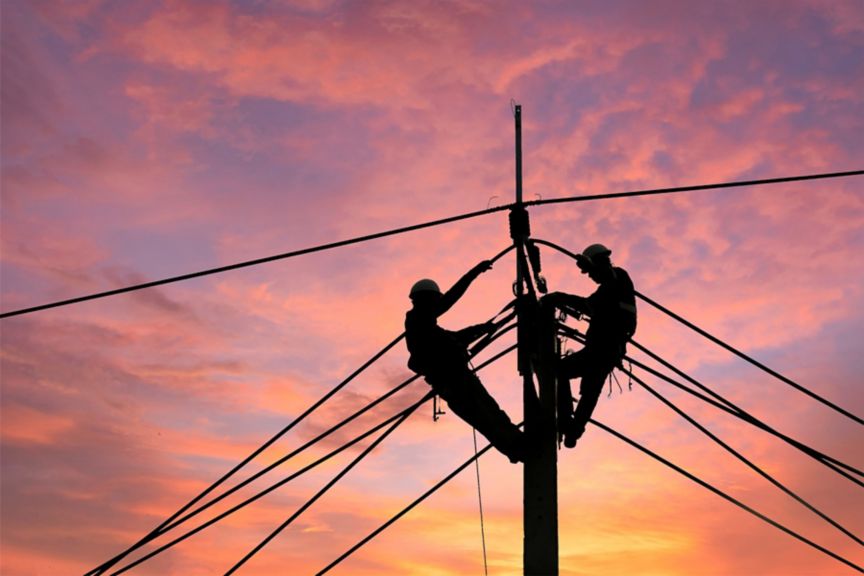

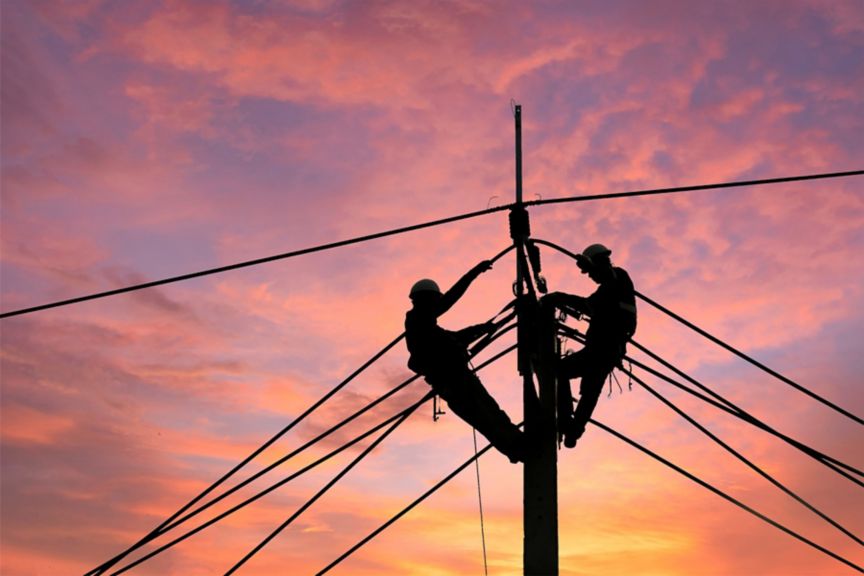

What is your first thought when you see orange? In the electrical utility industry, safety is often the first thing that comes to mind with the bright color orange. Where do we see this? In cones marking a working area, on highly visible vests being worn by workers and in cover-up garments. Line hoses, blankets, insulator covers and tagging devices are all examples of items we associate with orange that protect workers in the electrical utility industry.

A utility pole may have many bright orange items placed on it, especially when linemen take on the extremely dangerous job of maintaining the system without turning the power off. You may see a pole cover wrapped around the pole, line hoses on the conductors (power lines), insulator covers on the pole hardware and rubber blankets to cover any gaps. When this is done, many linemen call the utility pole a “Salisbury Tree”: that’s how well-known Honeywell Salisbury has become over the century-plus it has been in business.

History of the line hose

Salisbury has been setting industry standards for the electrical utility industry since 1855. Salisbury, which became part of the Honeywell family of companies in 2006, has been trusted for more than 165 years to provide high-quality safety products for this high-risk sector.

Salisbury pioneered the manufacturing of linemen's Rubber Protective Equipment. Back in the early 1900's, Salisbury was approached by a local utility in the Chicago area about general safety. The question raised was how to create a safer environment for linemen working on energized lines. Salisbury worked with the local utility by taking garden hoses and cutting them lengthwise in a way that would cover the lines. These hoses were then secured by electrical tape, and this led to the Salisbury-patented line hose in 1924.

Over the years, the line hose has evolved into the now-familiar high-quality orange rubber product seen across the U.S. and around the world. Honeywell Salisbury understands how important these are to the lives that depend on them and other safety products. Helping companies keep their workers protected on the job and helping to ensure they come home safely each day is a core value of Honeywell and the Salisbury brand.

Line hoses today and why the material matters

Line hoses, blankets and multiple covers are made of Type I natural (non-ozone resistant) and Type II SALCOR® synthetic rubber (resistant to ozone). Both provide electrical workers with the highest level of electrical insulating protection. SALCOR® Rubber is unique in how it remains flexible in cold weather and is resistant to ozone and UV rays. It is the preferred material for line hose and other insulating products because it easily withstands the elements without losing its flexibility or insulating properties. This application, one of hundreds filed in the U.S. Patent Office for Salisbury, has proved to be the most effective device for protecting linemen from accidental contact with energized lines, and is still regarded as indispensable to the electrical industry today.

Guards and covers are intended for brush contact applications. All guards can be coupled together to cover any length required within product specifications. The guards and covers are made from two different orange thermoplastics: Type I is an ABS standard cold weather, high-impact plastic and Type III is an ABS/PVC weather-resistant material that offers advantages in tensile and impact strength, hardness, UV stability and flame resistance.

Learn more

Today, Honeywell Salisbury is the leader in Personal Electrical Safety Protection. Each year, Honeywell helps companies keep over half a billion workers safer and more productive with our portfolio of worker-focused personal protective equipment across a number of industries. Honeywell Salisbury has the products you trust, the quality you expect and the safety you need.

About the Author: Russ Owen, CUSP, served in the U.S. Military for 21 years, 13 of which were spent in the U.S. Army doing power generation and distribution, and 6 years in power distribution safety. Now he is a senior technical lead at Honeywell Salisbury and serves on ASTM International committees (formerly known as the American Society for Testing and Materials). His experience as a lineman gives him first-hand insight into how to make our products both high-quality and user friendly.

Let's Connect!

Sign up to receive exclusive communications from Honeywell including product updates, technical information, new offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication.

Copyright © 2025 Honeywell International Inc

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

You cannot access this page as this product is not available in your country.