-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- 合作伙伴

- |

-

货币:本地化您的内容

您可以为此帐户设置首选货币

选择货币

货币- 选择您的货币

更新货币

更改货币将导致您当前的购物车被删除。单击“确定”继续

要保留当前的购物车,请单击“关闭”,然后在更改货币之前保存您的购物车

-

选择账户

切换帐户将更新您可用的产品目录。切换帐户时,您当前的购物车不会移动到您选择的新帐户。如果您再次登录此帐户,您当前的购物车将可用。

帐户# 帐户名称 城市 邮政编码 取消继续我的账户

You are browsing the product catalog for

You are viewing the overview and resources for

Whether you’re trying to meet peak season demand levels, adapt to new product profiles, achieve new levels of overall equipment effectiveness, or meet changing customer requirements, Honeywell Intelligrated Engineering Services provides a wide range of professional services to help you streamline your change management process. This multidisciplinary approach offers you an efficient resource for assessing your business requirements and developing custom-, cost-effective solutions to increase the effectiveness of your operations.

Maintain Best Practices While Minimizing Downtime

Maintaining the uptime of material handling equipment (MHE) is critical to your operational success, especially when you consider that most downtime is preventable. Audits and assessments can maximize the efficiency of your operation, while identifying asset, maintenance and functional opportunities.

The Honeywell Intelligrated Lifecycle Support Services team provides levels of experience and expertise unmatched by any third-party provider. They have a deeper understanding of your system’s design, maintenance and requirements that only an original equipment manufacturer (OEM) can provide, plus robust data to back their claims and recommendations.

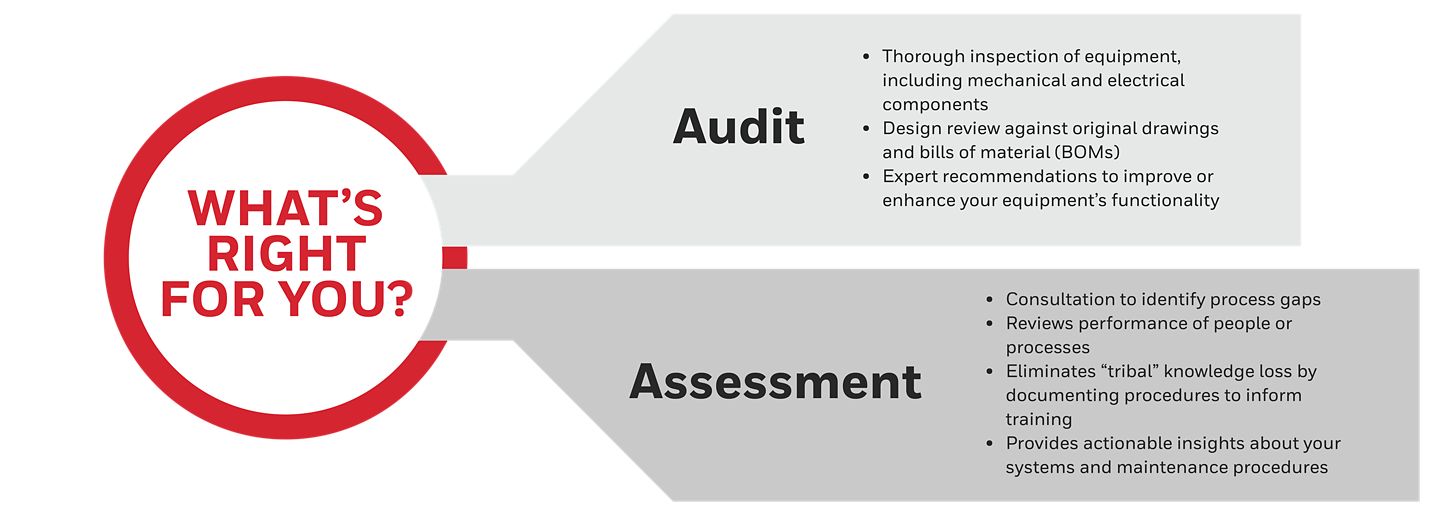

Audit or Assessment: Which Is Right for You?

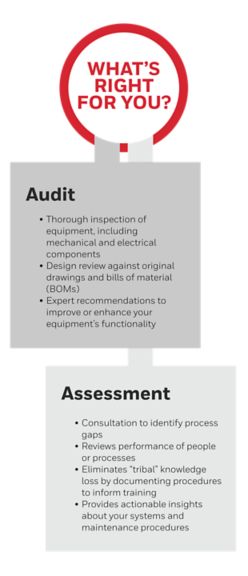

Audits

Audits provide you with expert consultation designed to identify process gaps and improve your operation. Whether you’re trying to identify unknown factors that are causing unscheduled downtime, struggling to meet maintenance schedules or key performance indicators (KPIs), or looking for strategies to improve performance, each audit is custom-tailored to meet your specific objectives.

Depending on your operation’s unique needs, our audits offer a variety of options. This variable scope can include any combination of the following:

![]()

Preventive Maintenance Audits

Preventive maintenance audits evaluate your maintenance standards, practices and systems to ensure that those systems are getting the maintenance they need to function at optimum capacity.

![]()

Technician Proficiency Audits

Technician proficiency audits assess the aptitude of your technicians to learn how efficiently they’re performing, identify potential expertise gaps, and recommend opportunities for skill improvement.

![]()

Field Maintenance Audits

Field maintenance audits provide a general overview of your equipment and maintenance practices.

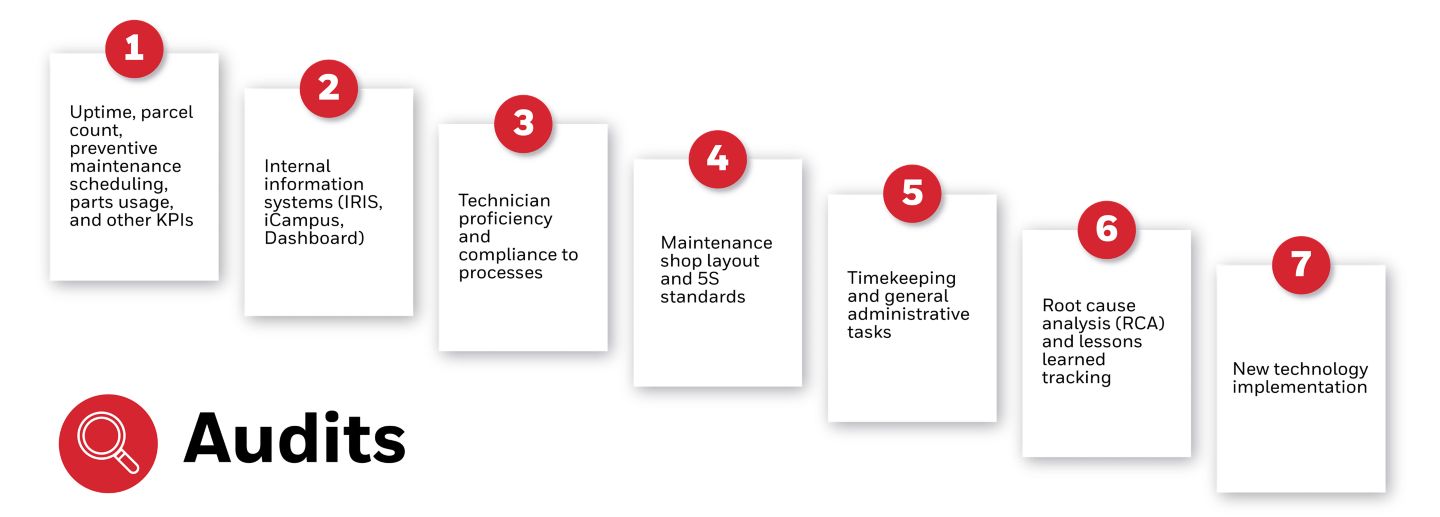

Assessments

Assessments can help your organization to prevent issues and preserve system uptime by proactively evaluating overall system performance and health risks. An expert assessment team deploys a proven, field-tested approach to gauge operational performance and conditions against established benchmarks.

Every assessment includes the following services and deliverables:

![]()

Reliability Assessments

Reliability assessments evaluate your equipment’s operational condition and functionality levels. You’ll get a detailed inspection of critical components, plus root cause analysis (RCA) and prioritization of maintenance actions or part replacements. The Honeywell Intelligrated team will also recommend engineered solutions, if needed, to bring equipment back to designed operating standards or reduce the risk of unplanned downtime.

![]()

Optimization Assessments

Optimization assessments review the effectiveness of maintenance programs and seek to optimize operator interactions with MHE. You’ll get recommendations for best-in-class asset management, with a focus on increasing throughput.

Changes to Business Operations

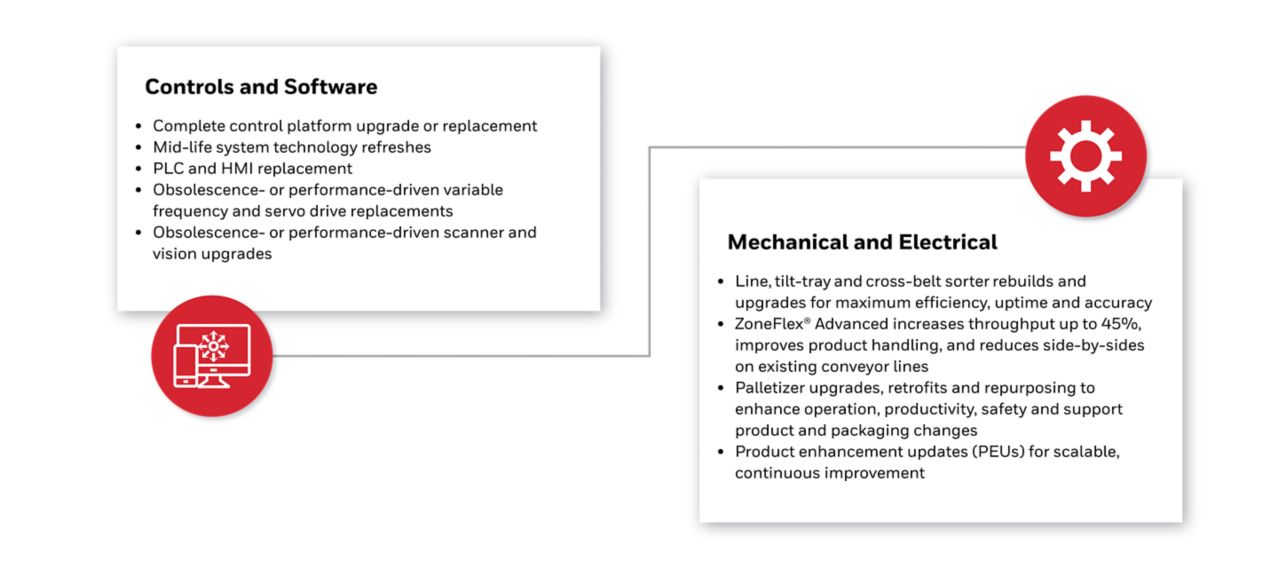

As you confront the challenges of modernizing legacy control systems, Honeywell Intelligrated Engineering Services provides obsolescence planning for critical control system components. These projects help you reconcile obsolescence while providing modern enhancements to deliver increased system capacity, flexibility and longevity. Modifications and upgrades include the following services:

A Better Way to Maintain your Alvey Palletizer

Alvey Palletizer Overhaul by Honeywell IntelligratedThe Alvey Palletizer Overhaul empowers customers to reduce downtime, control costs, and boost productivity through a comprehensive overhaul program tailored to the unique needs of Alvey palletizers. With simplified service planning, faster procurement, and expert-backed support, this program extends asset life and enhances operational efficiency.

Related Content

Complete the form below to get in touch with our experts and discuss your specific needs

订阅我们!

立即注册以通过电话、邮件等电子通信方式接收霍尼韦尔产品更新、技术信息、新品发布、活动和新闻、问卷调查、特别优惠等相关主题的独家营销信息。

Copyright © 2025 Honeywell International Inc